Processing to custom specification

We supply a large number of bespoke products to specification for our customers every day. Our employees fulfil special requirements with a practiced eye for the necessary and the extraordinary.

Mechanical engineering and the various forms of surface treatment require expertise and precision. We have an extensive range of approvals and certificates to ensure the highest quality processing standards according to requirement.

We have the following approvals and certificates for our processing service: processing approval according to AD 2000-W0, QM system according to PED 2014/68/EG, and re-stamping agreement according to DIN EN 764-5.

Mechanical processing

Special parts according to drawing or prefabricated parts in stock, we provide pipe connections ready to install in the highest quality. The pipe-cutting centre at our logistics centre in Beucha, Leipzig, will ensure that your pipes are cut to a high level of precision according to your specification. The service range in mechanical processing at rff includes the following:

- Pipes

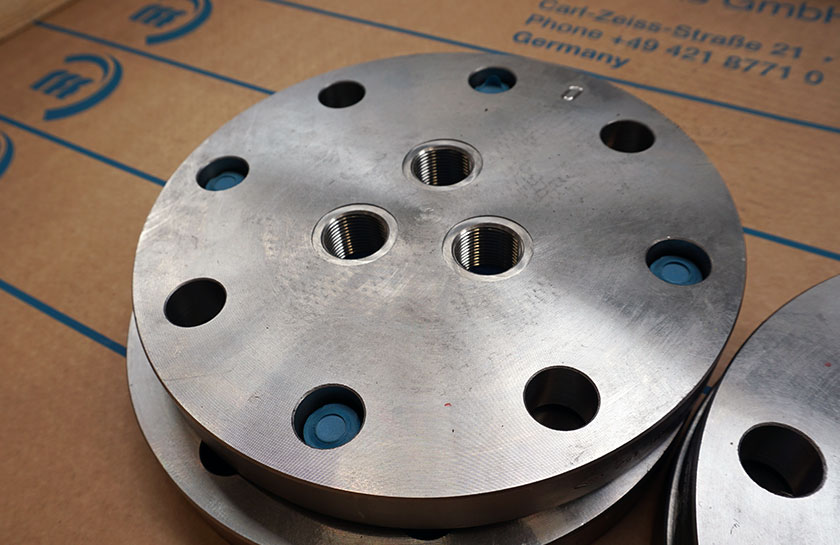

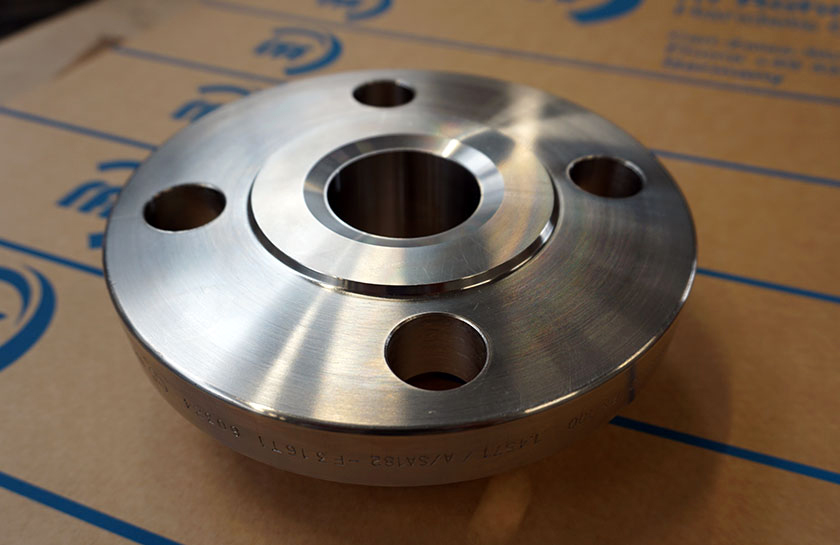

Cutting at our own pipe-cutting centre. Bevelling, drilling, bending, threading, necking. - Flanges

Face machining, tongue and groove, male and female, RTJ groove, hollowing, tapering, drilling (smooth or tapped), inner and outer edge machining, tapped holes. - Butt weld fittings

Bevelling, tapering, weld pig guide bars into tees. - Elbows

Bevelling, tapering, cutting. - Prefabrication of pipeline components

By isometry and pipe classes.

Surface treatment

Proper corrosion protection plays an essential role in keeping systems operating safely in the long term. We provide various surface treatment options optimally tailored to corrosion load and protection period in all pipeline components. Our range of surface treatment services includes the following:

- Blasting

According to DIN EN 12944-4 such as SA 2.5 - Primer and coating

Inside and outside according to DIN EN ISO 12944-5 or customer specification - Galvanisation

Hot-dip and electro-galvanising - PE insulation

According to DIN EN ISO 10289/10290/10309, all versions - Cement-mortar linings

According to DIN EN 10298, all versions - Other surface treatments

Rilsan coating, pickling and neutralisation, sanding, brushing and polishing