Our range of services

We supply a wide variety of services in addition to 14,000 tonnes of pipes, flanges, and butt weld fittings and equipment in tested quality.

Our customers benefit from a service range designed to the requirements of different industries since 1976. Here is an opportunity to learn more about our services.

Our services at a glance

Our performance at rff is reflected not only in our wide range of products in stock but also in the many services that go with our extensive delivery programme. We are an ideal supplier for bespoke services in pipes and pipe connections according to DIN, EN and ASME.

We set the standards in every area encompasses within our service range. Learn more about the possibilities.

- Pipes, seamless and welded, uncoated and coated

- Flanges, collars and rings, forged, rolled, bent and welded

- Seamless and welded fittings, tees, reducers, caps, special fittings, Part 1 / EN Type A, Part 2 / EN Type B

- All types of seamless and welded elbows, Part 1 / Type A – Part 2 / Type B

- Special elbows, pipe bends (narrow bends) inductive and cold-formed, all radii, also with extended legs

- Heads, collars, pipe clamps, U-bolts

- Gaskets, bolts and nuts, stud bolts

- High pressure, steel and malleable fittings

- Couplings and valves

- Steel bars, hollow steel bars, plates

- Special parts according to specification / drawing

- Material qualities: Non-alloyed, non-alloyed heat-resistant, alloyed heat-resistant, low-temperature, fine grain steels, high yield steels, stainless steel, high temperature steels, special steels, sour gas materials, non-ferrous metals, duplex und alloy

- Pipes cutting, bevelling, drilling, bending, thread cutting

- Flanges face machining, e.g. tongue and groove, male and female, tapering of ring type joint, drilling (smooth and tapped), machining of edges (inside and outside), tapped holes

- Fittings bevelling, tapering, pig guide bars welded into tees

- Elbows bevelling, tapering, cutting into graduated sections

- Prefabrication of line pipe parts according to isometric drawings and pipe classes

- Blasting according to required class, e.g. SA 2,5

- Interior and exterior primer according to specification, e.g. with epoxy resin or other

- Galvanising, hot-dip galvanising, zinc plating

- PE insulation, all types

- Interior cement coating, all types

- Rilsan coating

- Pickling and passivating

- Grinding and brushing

- Polishing, mechanical or electrolyticpolishing

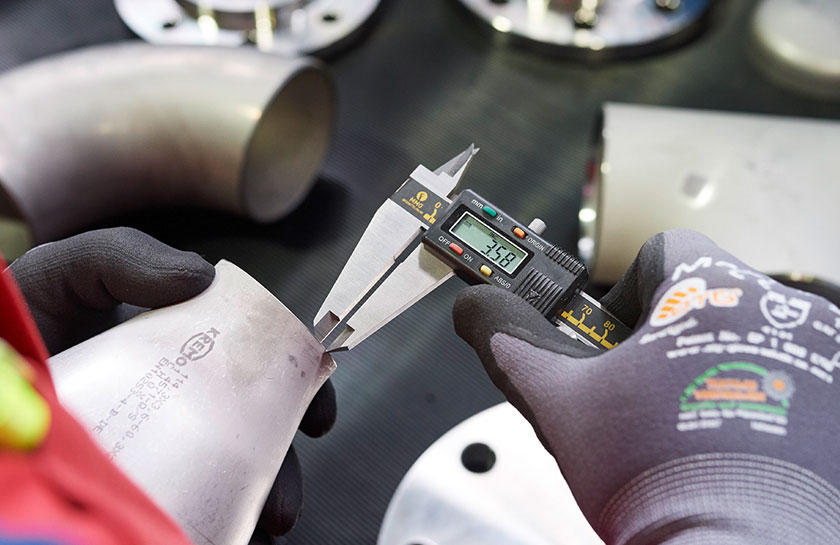

- Ultrasonic (U.S.), surface crack detection, magnetic particle testing

- Mill test reports (MTR) according to DIN EN 10204, 3.2 by TÜV or LR, DNV/GL, LR, BV, ABS, RINA or other in compliance with customer specifications

- Impact test

- Tensile test at room temperature

- Hot tensile test

- Folding test, widening test, ring expanding test

- HIC-Test / HUEY-Test for sour gas affected pipe components

- Testing to customer specification

- Marking with manual marking punches and embossing stamps

- Hard stamping with electromagnetic dot marking

- Colour marking

- Component marking, individual part or packing unit labelling

- Barcode labeling

- Account number, drawing number and other

- Logistics centre in Stuhr/Bremen, Beucha/Leipzig and Erkrath/Düsseldorf

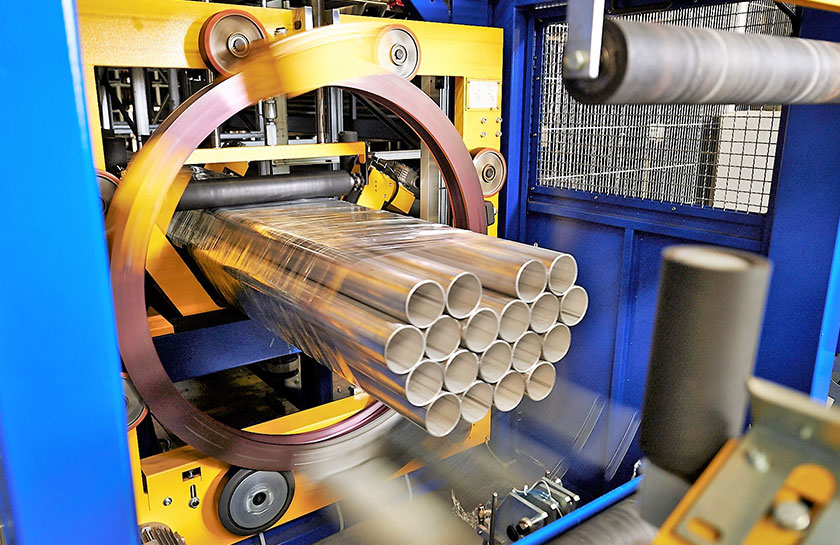

- Order picking from fully automated pipe stocks systems and small parts storage systems, high rack storage system

- Disposable and reusable packaging

- Export packaging according to specifications, e.g. according to IPPC standard

- Shrink wrap packaging

- Individual and bundle packaging

- Material supply and storage in rff own containers

- Own modern fleet

- Shipping with long-standing contract carriers, regular transit time 24 to 48 hours

- Express and courier services, TNT innight and overnight service

- Parcel service

- Projects are management by designated project teams

- Shutdown support, preplanning and storage

- Deadline monitoring / expediting

- Regular status reports

- Bill of materials (BOM) preparation according to isometric drawing

- Order picking and labelling per assembly / isometric drawing

- Designated project-specific warehouse space

- Internal / external inspection

- Colli lists and outgoing goods reports

- Unmistakeable Mill test report (MTR) number system

- 6-fold MTR backup

- Immediate access to MTRs for telephone inquiries

- Additional Information / barcoe directly on MTR acc. to customers specification

- MTRs enclosed with goods delivery and / or invoice

- Online MTR access

- MTRs deliverable via email or on datastore

- MTRs deliverable in multiple languages

- Shipping documents and MTR cover letter with heat numbers

- Wall thickness calculations according to DIN EN 1594, AD-B2, AD-B3, AD-B9 or TRD 301, on request TÜV-approved

- Comprehensive process control

- Online access to all logistics centre inventories from all rff locations

- Customised B2B solutions

- Marketplace solutions

- tem definition based on e Class characteristics

- Order tracking and online catalogue Service via Website and "my rff", access via www.rff.de/en

- Electronic invoices

- Invoice settlement in the credit note procedure

- Quality Management acc. to DIN EN ISO 9001

- Environmental Management acc. to DIN EN ISO 14001

- Occupational health and safety Management acc. to DIN ISO 45001

- Processor of materials acc. to AD2000 leaflet W0

- TÜV restamping authorisation acc. to DIN EN 764-5 for acceptance certificates DIN EN 10204 / 3.1

- Certified acc. to Pressure Equipment Directive 2014/68/EG

- Approved supplier acc. to KTA 1401

- Inhouse test equipment for spectral analyses, hardness testing and surface roughness measurements

- Inspection of all incoming goods for radioactivity

- Specific warehouse bin assigment system

- Single Batch / heat storage

- Ongoing education and further training programmes to increase employee expertise

'A comprehensive range of service allows us to provide our customers with optimised solutions.'

Michael Allexi, Managing Director, Sales and Marketing